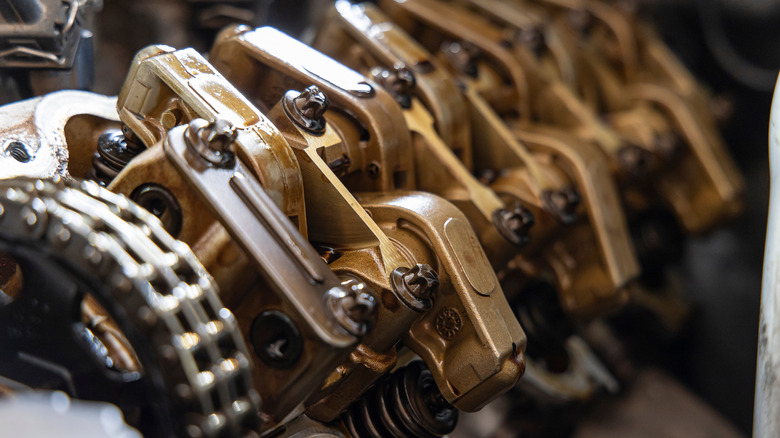

Sorry, solid lifters, you make a wonderful typewriter clack and allow for intoxicatingly high rpms, but you can’t be surprised that manufacturers slowly moved to hydraulic lifters for most engines ever since Cadillac introduced them in the mighty V16. Hydraulic lifters are just easier to live with on a daily basis. They don’t require frequent adjustment and, assuming they’re working properly, are as silent as a marshmallow dropping onto a bed of feathers in moon gravity. Unless low valvetrain inertia, mechanical simplicity, obsessive-compulsive control over valve timing, and ultra-aggressive cam profiles are the target of the engine builder, there’s really no need to introduce another part that requires constant care the way solid lifters do.

Let’s take Honda as an example. Honda used to be a champion of solid lifters because high revs were a major goal. Now, solid lifters are gone from Honda’s mass-production cars/SUVs/minivans. The J35Y6 V6 was Honda’s final engine using solid lifters, having been replaced in 2023. Though naturally aspirated V6s are going extinct, Honda continues to refine the J35, switching to hydraulic lifters for the J35Y8. This change eliminated the need for valve adjustment and allows for neat tricks like depressurizing the lifters to keep the valves shut during 3-cylinder mode.

Automakers want reliability and simplicity for owners

Solid lifters are fantastic at transferring energy from a cam lobe or rocker arm because they’re essentially a little solid cylinder of metal. They can be flat on one end, relying on proper lubrication to avoid scraping off material every time the cam actuates them, or they can have rollers on the end to reduce friction and allow for more aggressive grinds and higher rpm. The thing is, solid rollers also have to have careful lash settings to maintain optimal valve travel, and they won’t stay put permanently thanks to the effects of thermal expansion and getting hit by rockers or cam lobes all the time.

Modern metallurgy and smart designs certainly extend how long a solid-lifter engine will stay adjusted, but it still ain’t forever. Carmakers love it when they can use parts that require little to no maintenance, even when such a claim is patently absurd, such as with “lifetime transmission fluids” in sealed transmissions. The M110 inline-6 in ’70s and ’80s W123 Mercedes 280Es needed valve adjustments every 10,000 miles. You think Mercedes would sell an engine in 2025 with 10,000-mile valve adjustment interval requirements? Or even 20,000? Except for maybe a track-focused Black Series model, it’s pretty unlikely.

Hydraulic lifters don’t need adjustment, period. Yes, they’re heavier than solid lifters and are more complicated, featuring little pistons that rely on oil pressure to transfer energy from the cam to the valve. However, the benefit is that component wear becomes effectively nil because that little piston prevents thermal expansion from ruining precision-set lash. The cushioning effect and weight of hydraulic lifters limit rpm and response, but not enough to be a problem for 99% of driving conditions.

Silence is golden, apparently

Listen to that YouTube video from Dan Hopkins where he records the solid lifters ticking away on an early ’70s Corvette LT1 350. Kinda sounds like a sewing machine is running next to the idling ‘Vette. You can squarely thank the solid lifters for that, which is another reason why they’ve all but disappeared from your everyday commuter car: the quest for quiet.

Automakers want to make your drive like sitting in a living room, even if it means making the interior so silent, it’s hard to hear emergency vehicles. Take a drive in an ’84 8-valve SOHC Saab 900 Turbo and you can’t miss those clattering lifters. Then hop in a later Saab 900 with 16-valve DOHC heads sporting hydraulic lifters, and that Swiss watch tick is gone. Hooray, NVH is improved. Whee.

If automakers want a seen-but-not-heard engine, hydraulic lifters are the way to go. Solid lifters, in addition to being good at transferring energy, are also really good at transferring sound. The cushion of a hydraulic lifter’s piston not only fights thermal expansion, but also noise. So, if you’re building your ultimate drag racing machine, weekend-warrior street rod, or just don’t mind breaking out your tools and making valve adjustments every so often, go for the solid lifters. Don’t give in to manufacturers who want to coddle car owners with “don’t worry your pretty little head about it” zero-maintenance items!